An international team of academic and industrial researchers reported in Science a new way to manufacture elastomers that are as tough - and as resistant to fracture - as most elastomers, which are reinforced by additives.

The new process has been designed to distribute sacrificial bonds sparsely in the bulk, so that strain energy is dissipated over a large volume rather than funneled locally to propagate a crack. The process has a strong potential for industrial implementation and paves the way to a new generation of elastomers.

The researchers also introduced a new, general technique to display how strain energy is dissipated through bond breakage, which enables them to locate and quantify the number of bonds that actually break.

Costantino Creton, CNRS Research Professor and Étienne Ducrot, ESPCI Graduate & UPMC PhD student, at the Science & Engineering of Soft Matter Laboratory (ESPCI/CNRS/UPMC). ©ESPCI ParisTech

Costantino Creton, CNRS Research Professor and Étienne Ducrot, ESPCI Graduate & UPMC PhD student, at the Science & Engineering of Soft Matter Laboratory (ESPCI/CNRS/UPMC). ©ESPCI ParisTech

Resolving conflicting demands on materials properties

The main challenge that scientists typically face when designing advanced materials is to achieve superior overall performance by resolving conflicting demands on materials properties. By default, such conflicts are initially mitigated by making sub-optimal trade-offs; incremental gains in performance are then achieved through various tricks, within the framework of the initial process.

Eventually, fully resolving these seemingly incompatible demands often requires rethinking the problem altogether and inventing an entirely new process that leaps forward by breaking new conceptual ground.

A team of scientists from ESPCI ParisTech, CNRS, TU Eindhoven and Royal DSM N.V. have done just that in the well-trodden field of rubbers and elastomers, where mechanical elasticity often conflicts with materials toughness and resistance to fracture. Indeed, the current, state-of-the-art solution developed by the rubber industry is to use inorganic fillers as additives, which help dissipate strain energy through vibrational modes rather than through fracture propagation. However, additives makes processing significantly more complex.

However, filler-free elastomers have better elasticity, as there is no energy dissipation through the extension-contraction cycles. Additionally, filler-free elastomers are typically lighter and more transparent.

The team of scientists took a step back to think about new ways to manufacture materials endowed with superior mechanical elasticity, yet without sacrificing their toughness and resistance to fracture and which retain the distinctive edge of filler-free elastomers (elasticity, lighter weight, optical transparency).

Inspired by the previous work done on double network hydrogels by Jian Ping Gong, they came up with the idea of making multiple interlaced polymer networks, one of which being pre-stretched by design, so as to provide toughness and play the role of a spread-out network of molecular fuses to dissipate strain energy through bond breakage.

With this design in mind, they leveraged the distinctive ability of elastomer networks to swell when immersed in a solvent and devised that such dilation may provide enough room for a second, interlaced network to be synthesized in situ.

Tougher than its parts. (A) By combining different network materials, tough double-network materials can be created. (B) Photo of a tough double-network hydrogel containing 90 wt % of water ©Takayuki Kurokawa

They demonstrated experimentally that this is indeed the case and that the swelling operation may even be repeated to interlace a third network. The resulting materials were indeed endowed simultaneously with superior mechanical elasticity and toughness, as well as resistance to fracture.

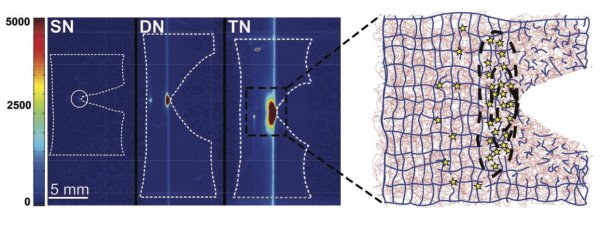

To demonstrate that toughness proceeds from the first network being maintained in a stretched state by the second (and third) interlaced network(s), and that it is the breakage of sacrificial bonds that dissipates strain energy and provides resistance to fracture, the researchers introduced, within the first network, specific molecular units that emit light when they break. As demonstrated in the movie, these units act like probes and bring to light the mechanism at play which confers the new material its unique performance.

Mapping of where bonds break during crack propagation.

(Left) Intensity-colorized images of propagating cracks on notched samples showing the light emission due to the breakage of bonds in single-, double- and triple-network samples. (Right) Schematic of the sacrificial bond-breaking mechanism in front of the crack tip for the double- and triple-networks.

This method is general and provides visual information about the loss of integrity of the first, stretched network. It enables the researchers to localize spatially where bonds break and to measure how many of them do. Also, this method shows that the toughening mechanism still operates when the material is further stretched, beyond the levels previously reached.

Last but not least, this three-tier design offers a number of flexible parameters that may be finely tuned to adjust the properties of the materials. Such process malleability makes this new design fully amenable to industrial development and implementation.

Exploring further

– the original publication:

Toughening Elastomers with Sacrificial Bonds and Watching Them Break

Etienne Ducrot, Yulan Chen, Markus Bulters, Rint P. Sijbesma, Costantino Creton

Science, 11 April 2014, Vol. 344 no. 6180 pp. 186-189

doi: 10.1126/science.1248494

– the movie showing experimental results:

– Étienne Ducrot’s PhD Thesis: "Innovative tough elastomers : Designed sacrificial bonds in multiple networks"

– other recent publications by ESPCI ParisTech research scientists in Science & Nature

– the Science & Engineering of Soft Matter Laboratory web site (UMR 7615 CNRS / ESPCI ParisTech / UPMC)

– Costantino Creton’s web page

– the web site of the Institute of Complex Molecular Systems at TU Eindhoven

– the DSM web site

Press Coverage (selection)

– Materials both Tough and Soft (Perspective dans Science Magazine)

– Toughening Up Elastomers (Chemical & Engineering News)

– Sterk maar zacht kunstrubber (c2w.nl)

– Research team develops method to strengthen elastomers (Phys.org)

– A New Way to Toughen up Elastomers (Polymersolutions.com)

– КАК СДЕЛАТЬ ЭЛАСТОМЕРЫ ПРОЧНЕЕ? (Chemport.ru)

– Toughening Elastomers with Sacrificial Bonds and Watching them Break (stemcell8.cn)

– Rint Sijbesma in Science met artikel over nieuw soort kunstrubber (tue.nl)

– Sacrificial bonds for extra toughness (EurekAlert!)

– 为了更大的坚韧度而牺牲键合 (http://blog.sciencenet.cn)

– Elastisch en toch sterk kunstrubber (http://www.kennislink.nl, http://www.qviper.com)

– Как сделать эластомеры прочнее?. Химия. (wiki.ru)

– ‘Crosslinkers’ laten zien waar kunstrubber breekt (http://www.engineersonline.nl)

– “牺牲”键合力可强化水凝胶 (ScienceNet.cn)