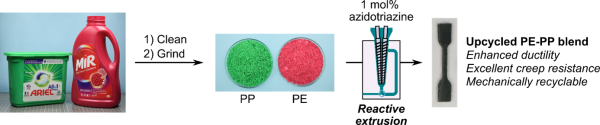

Polyethylene (PE) and polypropylene (PP) are the two most widely produced plastics today, but they rank among the least recycled. Objects made from PE and PP, such as bags, detergent bottles, cosmetics containers, or milk bottles to cite a few, are difficult to rapidly sort at recycling facilities. It would thus be ideal to directly reuse blends of PE and PP. Unfortunately, attempts to mechanically recycle blends of these two plastics result in low-value materials. Despite having similar chemical structures, PE and PP are incompatible with each another, which causes the resulting material to have poor mechanical properties. Although numerous strategies are known to address this issue, virtually none of them are practiced on an industrial scale because of a combination of high costs and impractical processing requirements. Thus, the vast majority of polyolefin waste in France today is incinerated for energy recovery.

In this context, a team of researchers led by Nathan Van Zee (CNRS Researcher) and Renaud Nicolaÿ (Professor of the ESPCI Paris) at the C3M Laboratory discovered a promising new strategy for upcycling polyolefin blends into high-performance materials. As recently reported in the Journal of the American Chemical Society, this process is based on the fascinating chemistry of azidotriazines, which are molecules that are able to form new chemical bonds with polyolefins at high temperature. Thomas Vialon, engineer of the ESPCI Paris – PSL who recently defended his PhD thesis, was the lead author of this study. He exploited this chemistry using reactive extrusion, a solvent-free process that is used in industry for transforming the structure of polymers. The resulting upcycled PE and PP blends are dynamic polymer networks that exhibit excellent tensile properties, creep resistance, and mechanical recyclability. This process was also found to be applicable to objects recovered from everyday life.

Upcycling polyolefins using azidotriazine chemistry is promising not only for future academic studies but also for industrial valorization, explains Van Zee. “Our approach is exciting because of the simplicity of the additive, the industrially relevant processing conditions, and the impressive mechanical properties of the resulting materials.” Vialon, Van Zee, and Nicolaÿ are co-inventors on a patent application based on this work.

Link to article: https://doi.org/10.1021/jacs.3c12303

Authors of this study from left to right: Nathan Van Zee, Thomas Vialon & Renaud Nicolaÿ

Authors of this study from left to right: Nathan Van Zee, Thomas Vialon & Renaud Nicolaÿ

Read full article in Journal of the American Chemical Society